radial

otr

bead to bead retreading

why the segmented bead to bead retread process?

PARALLAX IMAGE CAPTION HERE

PARALLAX IMAGE CAPTION HERE

The challenge common in retreading radial OTR tires has always been to make casing last as long as the second tread life.

The most common failure modes of radial OTR tires are:

1. Sidewall damage.

a. Radial cracking due to

fatigue.

b. Damage due to cuts and

scrapes

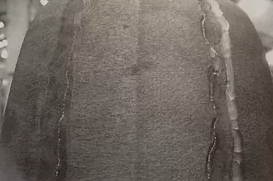

2. Casing belt edge separation.

a. In our experience, over

50% of all worn radial

casings 26.5-25 and larger

have some degree of edge

separation.

b. These separations are

uncovered in our buffing

process which follows the

contour of the worn tire.

c. Left untreated, these

separations will continue

to grow in size and the tire

will fail before the second

tread is worn out.

Since starting in the tire retread business in the 1940’s, our philosophy has been to produce a retreaded or repaired tire that delivers both new tire looks and performance. For that reason, all of our products are 100% mold cure, just as in new tire production.

Our Unicure line of light truck, truck, and OTR tires produces a finished product that is second to none in the industry. In 1993, as radial tires began taking on more of the OE market share, we realized the need to find a system to retread these tires that would match the dynamics unique to the mission profile of the radial tire in service. Unlike our competition, we decided trying to adapt an existing method was not an option. We sought out a system that would properly address the damage from stress, and wear and tear, in the sidewall of the tire. A system that would give the tire the best chance to wear out a second, third, and in some cases fourth tread life.

We decided on our Unicure OTR System as the only way to deliver this type of performance. We began with two presses, eight sizes, and three designs and have never looked back.

All of our tires receive a thorough visual inspection. Next, with a series of buffers varying by size, tires are buffed on a C&C-type, computer controlled buffer to an exact profile and diameter. Another inspection occurs after buff. Tires are then skived and filled in preparation for building. With various compounds to match application, tires are then built on a computer controlled builder, again to an exact profile and diameter.

The curing stage for our tires can be broken into two lines: modern, radial tread designs are cured in segmented, automatic presses and bias, with some square profile radial tires, tires are cured in two piece molds shoulder to shoulder.

Belt separations in the first and second belt usually can

be cut back to solid rubber.

Tires with separations below the second belt are rejected.

FINISHED TIRE

radial

otr

UNICURE CL3

our RADIAL OTR tires

UNICURE CH4-2400

UNICURE AP3

UNICURE CG2

UNICURE CH4

UNICURE CL4

UNICURE CL5

UNICURE CLG 550

UNICURE CML4

UNICURE CS3

UNICURE CV4

UNICURE CSG

UNICURE 875 CLD

UNICURE CEL4

The Best Value, performance & quality anywhere

SEARCH TIRES BY size OR design

Send

Thank You!

The form has been successfully sent.

This field is required.

This field is required.

This field is required.

Please Indicate How We Can Help:

This field is required.

This field is required.